How does your food business control potential hazards? What processes are you using to ensure you distribute safe food to all your customers at every delivery?

While there’s a long list of food safety systems out there, perhaps the one used across the most products and even countries is the Hazard Analysis and Critical Control Point (HACCP) system.

Both governments and industry regulators around the world either recommend a system based on the HACCP principles — or they demand it.

If you’re thinking about starting or updating your HACCP program, our guide to planning your first or second HACCP program will answer all your questions and set you and your planning team up for success.

The Hazard Analysis Critical Control Point (HACCP) is a management system used to control hazards related to food safety. It requires participants to analyze and control the biological, chemical, and physical hazards at all points of production from raw material production to consumption.

Although the HACCP is not a government program, governments in the United States and around the world have regulatory requirements that include introducing the HACCP system.

Where did it come from? The program began in the 1960s when NASA developed it as part of preparing for space travel.

In the U.S., its most recent application came via the Food Safety Modernization Act of 2010, which expanded the program to other areas of food processing. Today, there are four dedicated HACCPs under this umbrella including:

Back in 2005, Canadia made the HACCP system mandatory for meat and poultry processing. However, the Canadian Food Inspection Agency still recommends that the whole supply chain adopts the code, including both federally registered and non-federally registered businesses. (For the most up-to-date info, refer to the new Safe Food for Canadians regulations).

Are you based in the EU? Then, your need to follow HACCP principles began in 2006, when ‘Regulation (EC) No. 852/2004’ required almost all food and drink businesses across the EU to implement a food safety management program.

In Australia, the Australia New Zealand Food Standards Code Standard 3.2.1. requires you to have the HACCP system in place.

If your organization participates in food processing, then there’s a strong likelihood that you also need to create at least one HACCP plan.

As noted in the introduction, some countries or unions require all food and beverage businesses to use the HACCP system.

The United States uses a more granular system and requires you to implement the system If you participate in:

However, the FDA’s Food Safety Modernization Act 2010 actually requires a Food Safety Plan (HACCP by another name) for all other food processing businesses. You can see the full regulation under 21 CFR part 117.

Processing plants aren’t the only companies targeted by U.S. law. The FDA also wants retail and foodservice sectors to apply the HACCP principles. Although it’s not currently required in all cases because you are governed by state licensing and inspection processes as well as local regulations, HACCPs have already been successfully applied within these contexts.

However, in the U.S., you do need to create a HACCP plan if your restaurant or retail business uses any of the following ingredients:

You’ll notice that these ingredients are also strictly covered by the processing regulations noted above.

Yes, if your organization is named in local, state, or national regulations, then you must create and follow a HACCP and keep up-to-date with the latest regulatory changes.

Compliance and certification are two different things. The law may require you to comply by creating and implementing the HACCP system or using a food safety system based on HACCP principles.

However, certification is a second step that you may find you have the option of taking, depending on your market.

The HACCP program offers tangible benefits to food processing (and service and retail) businesses. HACCP isn’t a quality control system: it is a food safety system. However, it does have some tangential quality control benefits when followed correctly.

If you create and implement a program tailored to your products, then compliance can benefit you by:

These benefits ultimately inform customer confidence and protect your brand and operating budget from the damage caused by contaminated food.

We all understand that food safety is important. However, using a carefully planned system is critical because the issue with food quality and contamination is that it’s never contained to a single customer.

Chipotle’s woes earlier in the decade are a perfect example of this. While some of its issues stemmed from the produce that Chipotle purchased from local farms, regulators and inspectors also found that food handling practices played a role in some E. coli outbreaks. Several hazards cost Chipotle millions and put the company in the national headlines for all the wrong reasons.

There are five main industries typically required to implement HACCP. These include:

Retail and foodservice businesses may have fewer obligations compared to meat or dairy processing, depending on where you operate. Why is this the case? Your service or retail business is less likely to be subject to these standards because you typically don’t manufacture or produce food: you are often the customer. However, that doesn’t mean this sector of the industry doesn’t benefit from HACCP. Moreover, regulators are increasingly looking towards enforcing HACCP plans among these types of businesses.

Even if you don’t need a HACCP plan now, it can help you stay one step ahead of inspectors in the coming years.

You can begin to understand how to create and use the HACCP system by first learning its seven principles of HACCP. These include:

You should begin any major process in your food processing business by first conducting a hazard analysis. A hazard analysis involves identifying the most significant hazards as well as where they are most likely to occur in each step of the production process.

Use your team’s industry experience, product knowledge, epidemiological data, and information in the technical literature to identify potential risks to the consumer.

Document the hazards that you can prevent, control, or eliminate with your HACCP plan.

Critical control points (CCPs) are steps or procedures where you can eliminate (or control or prevent) the hazards you identified in principle one.

Your goal is to identify the potential CCPs and then add them to your plan using the CCP decision tree which requires you to ask:

You can find the full break down of the CCP decision tree, including instructions on using it, here.

Remember: you may find that one CCP may impact more than one hazard. It’s also common for one hazard to have multiple CCPs.

Critical limits (CLs) are the maximum/minimum value to which you must control parameters related to a CCP to reach the desired impact on the food safety hazard.

A CL is usually a measurement related to the hazard. These might include:

The measurements that apply to you depend on your industry and the regulatory standards (or scientific literature) that apply to the type of food you process and the methods used to do so.

Every CCP requires a thorough monitoring procedure that includes the CLs identified for it.

Your monitoring procedure needs to include:

Principle 5 expands on the monitoring processes that you identify in principle four. It creates a plan to follow when you deviate from the critical limit.

Your corrective action is multi-faceted because it includes:

Until now, the principles focused solely on monitoring processes and procedures to identify critical hazards and prevent them from impacting your production procedures. Principle 6 requires you to verify the validity of all the processes you identified thus far.

The verification activities chosen may include:

These activities also play a role in Principle 7.

The final principle focuses on the importance of keeping complete and accurate records of your HACCP plan.

Your records should include all activities, processes, and procedures identified in principles 1-6. They should also include information about your HACCP team and the relevant product descriptions.

These records are critical to your success with the HACCP plan. They not only serve as a point of referral for monitoring and auditing, but they also prove to regulators and customers that you produce food safely.

When working through the 7 Principles of HACCP, be sure to work in the other food safety practices and principles that pertain to your product and processes. Sanitation Standard Operating Procedures (SSOP’s) are mandatory for federally inspected meat and poultry operations. Good Manufacturing Practices (GMP), while not required, will support your HACCP plan and act as a quality and safety net.

HACCP programs manage the specific process hazards identified, but you can’t just launch yourself into developing a HACCP plan. First, you need to complete the appropriate prerequisite programs to gather the information you need to start your HACCP plan development.

According to the U.S. Department of Agriculture, you should think of prerequisite programs as a type of “good housekeeping.” They fall outside the HACCP plan but still inform the plan because they are within the system. Inspectors don’t apply the same criteria to your prerequisite programs as they will to your HACCP plan.

The goal of the prerequisite program is to inform the HACCP system and support your overall food safety system. They prevent potential hazards from reaching a point where they could impact food safety.

Your prerequisite programs aren’t just the introduction to the HACCP. Every prerequisite requires the same level of monitoring and auditing to demonstrate their effectiveness and employ corrective actions in case of failure.

While most of your prerequisite programs will make their way into the HACCP plan, not all will. You must keep records of all prerequisite programs mentioned in your HACCP plan (or hazard analysis or SSOP). Inspectors expect to review all records and supporting documentation for every HACCP plan.

Every organization’s prerequisite programs will differ based on the food you produce, the processes you use, and the purpose of your plant. Some of the programs that most production plants have in common include:

What is more, these programs don’t just apply to the factory floor. They apply to the whole building as well as your equipment including:

With a complete list of prerequisites prepared, you are ready to begin developing your HACCP plan.

Every organization’s HACCP plan form varies. You’re not just checking boxes. You’re creating product-specific plans that apply to the unique issues facing your business.

You can begin with five preliminary tasks that almost every organization will use to begin to develop its HACCP plan.

The steps to developing your HACCP plan include:

Putting together the right team is critical to the success of your exercise. Every team member needs specific knowledge of both your food product and your manufacturing processes to be able to contribute to the plan.

For the best results, you should create a multi-disciplinary team that includes leaders from across your organization. Ideally, you will include someone from:

Including local operational personnel is particularly important as they contribute an understanding of the day-to-day operations and can identify the limitations of corrective actions. It also adds an element of ownership among the teams who are responsible for overseeing the plan in real-time.

Some organizations find that they benefit from outside experts, who can contribute expert, impartial knowledge on hazards associated either with the product generally or the process specifically. However, regulators discourage you from relying solely on outside consultants or external teams because you risk developing a HACCP plan that is incomplete or erroneous. It may also not reflect your day-to-day activities, which means your personnel could struggle to comply with the HACCP.

Once your team is in place, their first introductory task as a team is to describe the food product(s). It should include:

Your distribution description should include whether you transport your food in frozen, refrigerated or ambient temperature form.

Next, you need to explain the intended use of the food. You should also list your intended consumer.

For example, if you make baby food suitable for children age 12 months and up, then you will note this. If you make gluten-free bread, you might include coeliacs and gluten-intolerant customers of all ages.

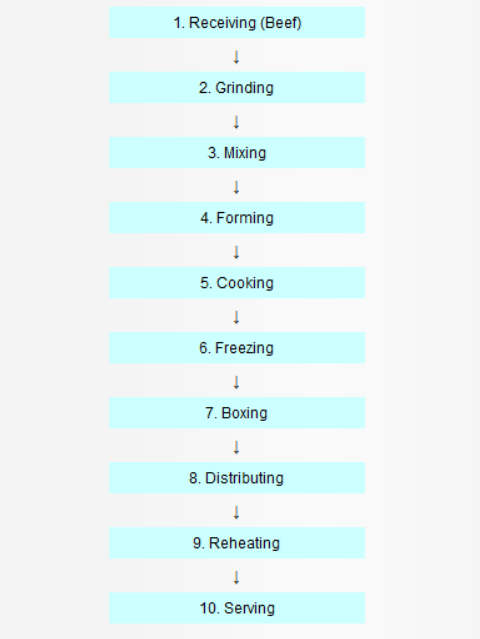

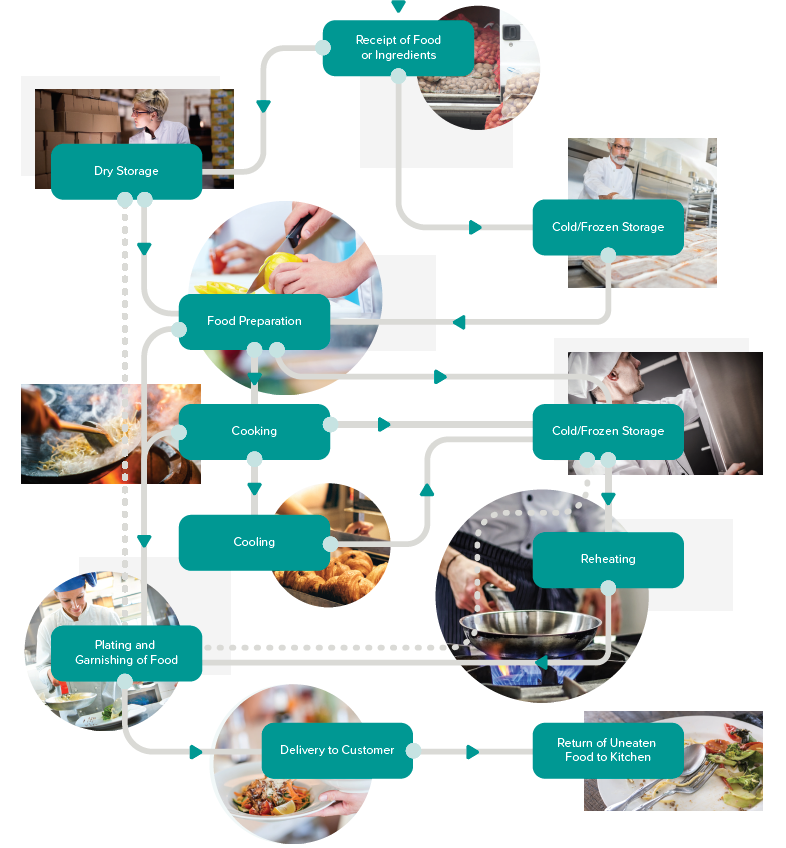

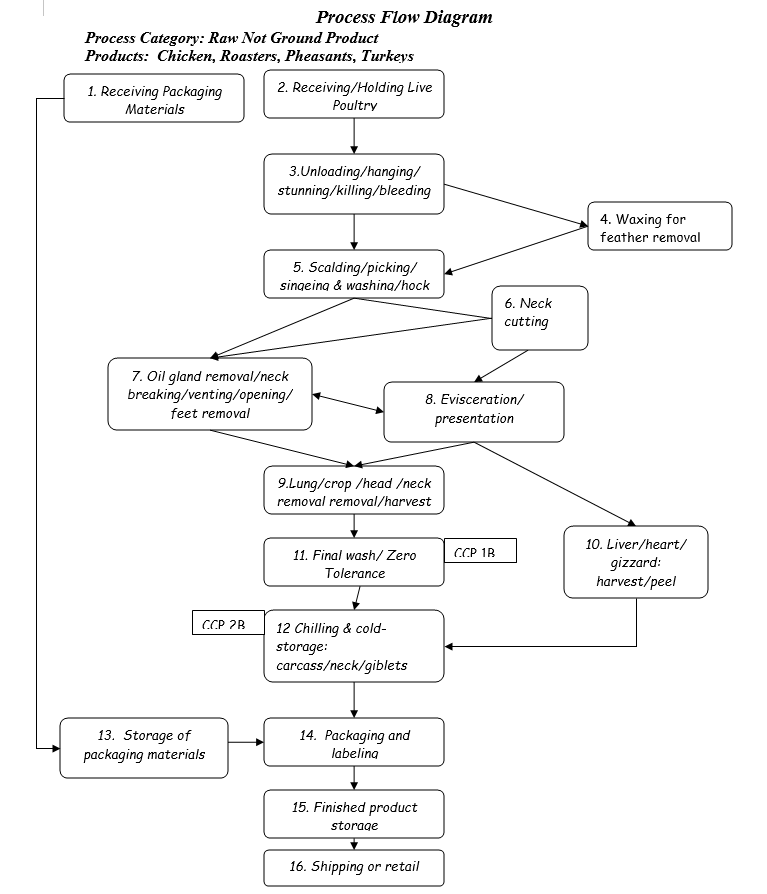

With the descriptions complete, the team then begins work on the flow diagram. The purpose of the diagram is to provide a simple outline of the process, so it doesn’t need to be detailed or complex. However, don’t mistake simplicity for a lack of completeness. You must include all the steps in the process that are under your establishment’s control.

You also need diagrams that include the steps in your food chain before and after you process the food. The team also benefits from a simple schematic of the facility, which aids in the chart development. It doesn’t need to be as complex as the facility’s engineering drawings.

A block type diagram is descriptive enough to use at this stage of the process. Remember that you don’t need to go into fine detail, but you should ensure every part of your process finds a place in the chart.

Almost every chart will start with “receiving” and go from there. We provided a few helpful examples from programs around the world you can use to develop your process flow diagram.

Collaborate and develop your process flow chart with this template.

Before proceeding with your plan, the team should review and verify the validity of the flow diagram. Be sure to do this with an on-site visit and walk-through and be prepared to modify the diagram as required based on your findings.

With your flow chart ready, you can now analyze your complete process for potential hazards.

After you have laid out your production processes and evaluated them for hazards, you will work through the seven principles of HACCP discussed above. This involves evaluating potential hazards, identifying your CCPs, and determining how you will address deviations.

Walk through the principles step by step, documenting each one as you go.

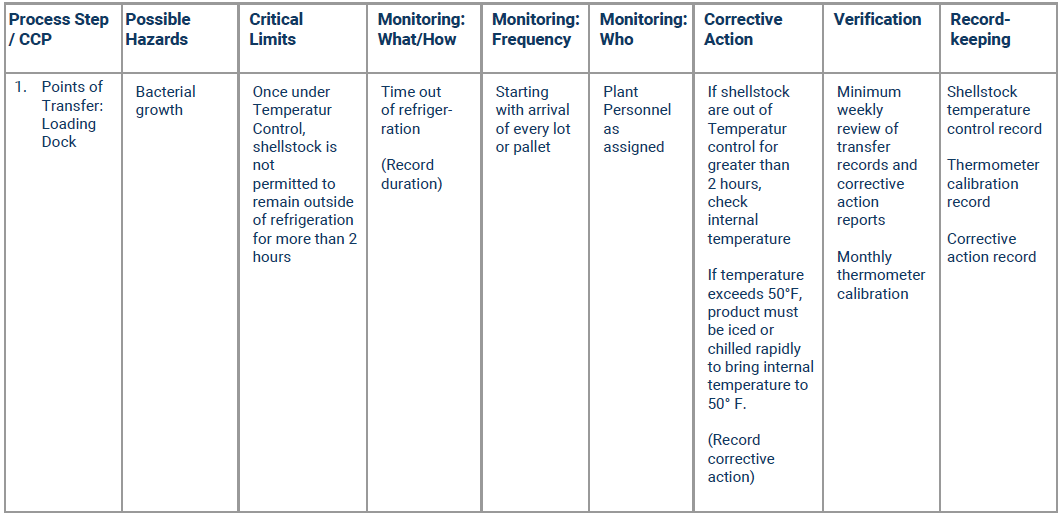

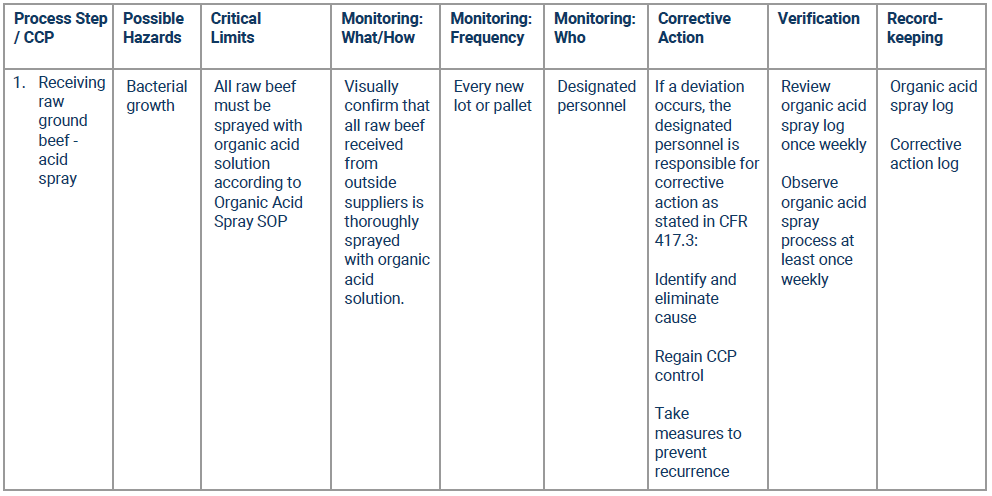

Your written HACCP plan will be built around the Critical Control Points you identified during your hazard analysis.

We put together a few examples of HACCP plans from various industries:

Download the blank HACCP Plan Template to begin outlining your plan. Fill out the template step by step for the first time or audit an existing plan.

Your completed HACCP plan will include:

Finally, train your employees to implement your plan and to record the monitoring and validation tasks associated with it.

Overlap between HACCP and Other Regulations

The HACCP overlaps with several other national and international regulations and standards. If these standards also apply to you, it’s helpful to plan with these in mind when designing your HACCP plan.

US-based food production plants will find that there’s overlap between their HACCP and their OSHA requirements.

OSHA requires you to beware of chemicals associated with processing industry accidents such as ammonia, chlorine, carbon dioxide, and more. The food processing industry uses a vast number of cleaners and sanitizers, and most need to be incorporated into your OSHA chemical hazards plan.

You may find that your HACCP systems may require you to change the type and strength of your cleaners and sanitizing agents. For example, OSHA notes that poultry processing has increased the use of chlorine sprays and rinses.

It’s important to account for these in your:

SQF is another food safety management system that requires the use of the HACCP. You’ll develop and implement your organization’s HACCP as part of completing your application to become SQF certified.

It’s helpful to think of SQF as picking up where HACCP requirements end. The SQF certification has stricter requirements of which the HACCP system is a part.

ISO 22000 is the international ISO standard that lists the food safety management system requirements. Like HACCP, any organization operating at any link in the food chain can participate when their goal is to improve food safety.

While there is some overlap thanks to the generality used by ISO standards, there are some additional components required for the ISO itself, including among external communication, good practices, and documentation. Additionally, the ISO 2200 integrates the seven HACCP system principles and the prerequisite programs rather than only auditing the HACCP system itself.

Good Manufacturing Practice is another safety system used to meet legal and quality requirements in the food processing and manufacturing industries.

You’ll find that your HACCP is part of your GMP, but both are important parts of the other.

It’s vital to complete both your GMP and your correlating HACCP to the highest standard if you seek certification. A certification audit often begins with a GMP examination.

SSOPs describe your plant’s cleaning program and dictate the records used to monitor your sanitation. There’s overlap between SSOPs and the HACCP because the SSOP is usually a prerequisite program for the HACCP plan.

The type and scope of SSOP you need depend on your establishment as well as the regulatory requirements put in place by your locality.

If you fall under OSHA’s regulatory oversight, be sure to note the OSHA section above to learn more about the overlap between these three components (OSHA, HACCP, SSOP).

As you design your HACCP system, it’s helpful to train both your dedicated HACCP team and those who will implement the system on the ground. Most food safety programs offer HACCP courses. Availability and provider depend on your geographic location.

If your plant is in the United States, you might choose to work with the NSF’s HACCP program, which boasts an International HACCP Alliance accreditation and is available in training centers, on-site, and as a self-paced eLearning course.

By now, you’ve learned that there’s a lot of work involved in developing a HACCP system for your organization. You also learned a bit about the benefits, which include better risk management, safer products, and even some specific quality improvement elements. What does it all mean in the real world?

In an academic paper published on the HACCP system, Peter Bryar provided three case study examples that answer precisely this question.

The first case study featured one of the largest horticultural businesses in Australia. It grew and packed produce both on its own and through a network of growers. The hazard analysis (principle 1) of the HACCP immediately identified weaknesses in their current system by encouraging them to look beyond the existing system and into their suppliers.

According to Bryar, when the company completed its HACCP system, it had new confidence about its ability to expand without increasing its food safety risks.

Bryar’s second case study included a different large horticultural company and evaluated their process flowchart and hazard analysis. The company found that an unacceptable amount of their produce failed to meet their customer’s expectations.

At the same time, their HACCP found that the food was safe and was suitable for using elsewhere, rather than dumping it. The company was then able to sell them onto another customer who used the product for jams and sauces.

In the third case study, Bryar looked at a smaller enterprise that also sold produce (strawberries). The small business found that chemical residue was a big risk because strawberries require a significant amount of treatment to manage disease and pests.

So, the business looked for other ways to protect the crops without the need for chemical sprays. The business owner settled a new integrated pest management system. It not only reduced the chemical use hazard but also saved the business significant amounts both in labor and costs.

Because the HACCP process required these businesses to look so closely at their processes, they not only found new hazards but also new opportunities to either save money or find new revenue streams.

Developing, implementing, and monitoring the HACCP plan requires a mountain of paperwork. That same mountain also demands regular and complete updates.

There’s a vast amount of food safety compliance software available, ranging from web-based applications to mobile apps, to help you keep everything organized.

Some of the dedicated HACCP compliance software systems include:

Once you implement your HACCP plan, you have the option or obligation to seek HACCP certification.

HACCP certification is an international standard that confirms your HACCP plan effectively controls your food safety operations.

As you already know, HACCP isn’t a government program — even if it is required by many state and national governments around the world. So, who provides HACCP certification, if not a government body?

External certification authorities provide the service to businesses around the world. You can find your local certifying body by checking with Exemplar Global, which is not only the professional body for food auditors but also certifies external food safety auditors. If you’re in the U.S., you can seek HACCP certification through NSF.

Once your HACCP system is ready and running, you can tender third-party certification bodies and find the right auditor for your company.

Be sure to check with your local food safety authority for recommendations or requirements.

Are there any benefits of HACCP certification beyond fulfilling any regulatory requirements you might have?

Beyond mandatory compliance, HACCP certification makes good business sense.

Certification not only requires you to complete these safety processes, but it requires you to complete the work to a standard in which an external auditor reviews your work and validates it.

Not only does it ensure that you produce and distribute food that is safe for consumption, but it also looks good when you attempt to branch out into other markets. It can even set you apart from your competition, who may use a HACCP plan but never sought certification.

Yes, as long as you don’t have a requirement from your government or government in a market you intend to enter, then you can develop and implement HACCP plans for your products without seeking certification.

You should always refer to your local health authority as to whether or not certification is required.

Most independent restaurant or retail owners don’t typically seek certification, even when they do implement a HACCP plan. Certification is usually limited to processors and manufacturers.

To become certified, you need to undergo and then pass a HACCP audit with your chosen external auditor. You can only do this after you have already implemented the HACCP plan in your facility.

A ‘test’ audit is the best way to identify whether you’re ready for an external audit. But these are vital to the success of your HACCP plan whether or not you intend to seek certification.

An internal audit ensures that everything is in place and all processes operate the way they should. Ideally, you’ll have an external party complete the internal audit on your behalf. Don’t rely on your HACCP team. Even though they’re well-versed in your particular systems, they can miss essential items that could cause you to fail your certification audit.

Why hold your internal audit two months out? It will give you time to address any issues that appear and put them in place well before your external auditor arrives. The last thing you want is for it to become clear to the certification auditor that you took a last-minute approach to fully implementing your HACCP. The person communicating with the auditor should be able to explain concrete processes — not the things you “try” or “should” do.

Although the HACCP plan development was largely limited to your HACCP team, you need all hands on deck for the audit. Everyone who has anything to do with HACCP implementation — even tangentially — needs to be involved.

At the meeting, you should make sure that everyone understands their job descriptions and their role in the HACCP. They should also understand the hazards and the CCPs outlined in the plan. If they engaged with any corrective actions, then they should have a complete understanding of these, too.

Completing your documentation is an essential step, but it differs for every business.

The documents involved depend on:

It’s important not to put off the documentation phase of the planning and implementation processes because these are the first things the auditor sees.

Your audit will include both a review of your Good Manufacturing Practice (GMP) and your documentation.

It’s vital to have all of your HACCP documentation (plans, charts, monitoring, records) available for the auditor to take away for an off-site review.

In most cases, your auditor will ask for your documentation before the official on-site facility audit. Working in this order allows the auditor to become familiar with your plan and better evaluate your strategy.

Ideally, you want both your HACCP team and the senior staff who oversee the implementation of the plan available to attend both the opening and closing meetings with the auditor.

Make sure you clear their schedules in advance and inform them of the meetings so they can prepare themselves.

Once you receive certification approval from your external auditor, they will inform you of the appropriate way to advertise or list yourself as a company with HACCP certification.

For example, you may receive a certificate for the auditor. However, you may also need to bring it to a registrar or regulatory agency to get it stamped in order for it to be valid.

Make sure you follow any local or national statutory obligations regarding prioritizing other certifications.

Don’t forget to follow the rules regarding expiration! Your certification may be good for three to five years depending on your local agency’s requirements.

Controlling safety hazards in your processing plan is your obligation as a participant in the food chain. Setting up and implementing a HACCP program can help you not only achieve your safety goals but also open up new markets and potentially even become more profitable. It also keeps you compliant with local, state, or national food safety regulations, which increasingly recommend HACCP programs to food businesses around the world.

The process begins with the five introductory steps before diving into the seven principles of HACCP. These exist not to be prescriptive but to guide your business, processes, and products through the process so you can make the most of the plan and customize it perfectly to your business.

As with all safety regulations, the crux of the program is the paperwork you keep, including both the documents for your safety system and the auditing and monitoring paperwork. Your paperwork is particularly critical if you intend to seek HACCP certification, so finding the right digital paperwork management system can better enable you to find success.